Faster production, minimise downtime

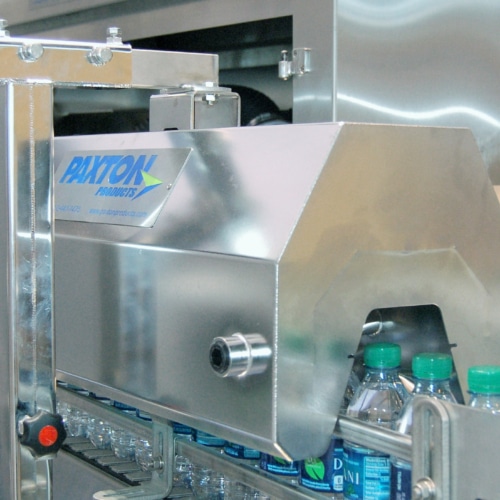

Air Knife Systems create powerful, laminar air flows that dry and prevent moisture contamination from affecting products on a production line.

Air Knife drying systems are energy efficient, time and cost saving in comparison to compressed air systems, and are suitable for a range of industry and product applications, pre and post packaging.

Benefits:

- Clean, moisture and oil-free air ensures rapid evaporation from objects

- Washdown enclosures to house the blower ensure GMP requirements are met, protect the blower from harsh cleaning chemicals, and reduce noise

- FDA Compliant 304 Stainless Steel air knives and manifolds suitable for harsh, corrosive, wash-down or sanitary environments

- Can be easily installed onto existing production lines

- Prevents water corrosion and water marks on packaging, cans and bottles

- Prevents moisture from saturating the air round objects on a conveyor belt

- Prevents natural levels of humidity from making contact with objects

- Ensures surfaces are fit for painting and labelling

- Ensures products are fit for packaging

See typical products & covered

High quality surfaces pre and post paintwork and labelling

Drying is key to a number of industry applications, including ensuring correct labelling, eliminating water damage/moisture corrosion, eliminating printer ink spoilage, ensuring high quality paint jobs. Air Knife Systems minimise the potential for low quality outputs and spoiled products.

Investment paybacks are often achieved in just a few months, sometimes in a matter of weeks, providing a superior return-on-investment.

Contact us to discuss your specfic requirements