On 12th March 2024, SolvAir were proud sponsors, with Carbonlite, of the Smithy Bridge Primary School F1 Team – the Smithy Speeders.

SolvAir Sponsor Smithy Speeders F1 Team

Milestone Birthday – Steve Hand

We are delighted to be celebrating a milestone birthday this month with our Sales Engineer, Steve Hand.

Nurdles in the news

The start of 2024 has seen a number of news stories on the problem of plastic nurdles in the environment.

2023 Year In Review

SolvAir: A Year of Growth, Achievements and Milestones – 2023 Annual Review

SolvAir Celebrates 20 Years!

We are delighted and honoured to announce that 2023 marked the 20th year that SolvAir has been in business.

Christmas 2023 – Opening Times

SolvAir is set to close for the Christmas break on Friday December 22nd, 2023 at 3:30 PM, and will reopen on Tuesday January 2nd, 2024, at 8:30 AM.

Gesete & BrauBeviale 2023 Visit

BrauBeviale 2023 – The Global Beverage Industry Unites!

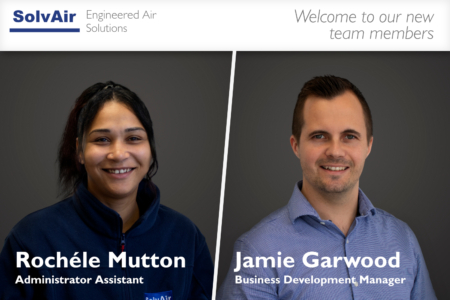

New SolvAir Team Members

Rochélle is our new Administrator Assistant, coordinating the day-to-day delivery of our services. Jamie is responsible for customer relationship management, including market research, forecasting and reporting.

SolvAir Launches Vortextubes.co.uk – Efficient Compressed Air Based Cooling Solutions

SolvAir, a leading innovator in air technology solutions, is proud to announce the launch of its new website, Vortextubes.co.uk. This cutting-edge platform aims to provide its customers with a comprehensive range of vortex-based cooling products, including vortex tubes, vortex coolers, cold air guns, and compressed air-based air knives.